Granuli molli del PVC dei fiocchi dei PP che fanno la linea della macchina

Panoramica Dimensioni della confezione 500,00 cm * 200,00 cm * 200,00 cm Peso lordo della confezione 2.700,000 kg Scagli;

Overview

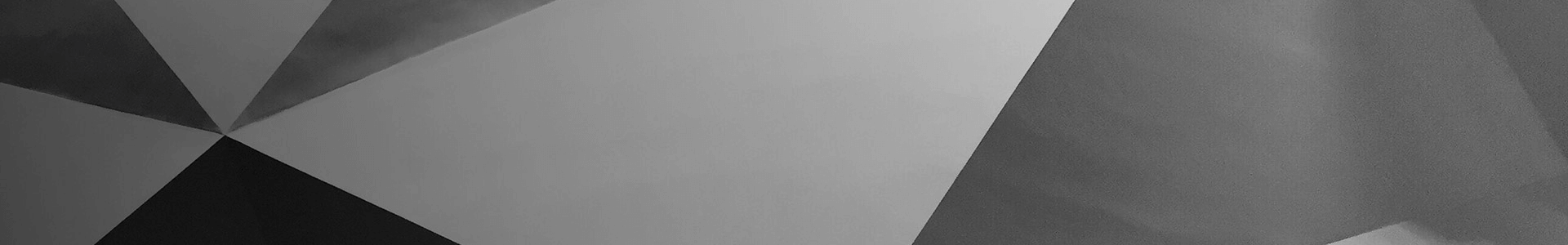

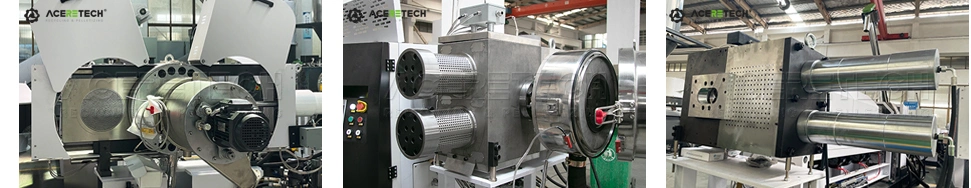

>> Multiple selection of smart feeding method: Plastic scraps can choose belt conveyor; Rolls' scraps can choose roll hauling off device;Feeding speed is automatically.>>> Strong crushing and compacting unit:Rotatory blades of compactor will cut up incoming scraps;Frictional heating will dry and compacts the materials;Feed from the compactor directly into the extruder.Sliding gate make it can handle both film and rigid scraps./p>>> Specialized single screw extruder: Equipped with high torque gearbox with integrated design; 34D to 36D processing section to gently melt the plastics;Bi-metal Screws and barrelsensure 2 times use life than usual.>>> Double-zone vacuum degassing system:Double-zone degassing can remove the volatiles efficiency;Equipped with vacuum tank, which store the impurities, small molecules or oil stains from the exhaust./p>>> Plate type double station filter: Cost - effective,Easy to operate;>>> Piston type large area filter:Suitable for heavy contaminated materialSuitable for large capacity recycling machine;>>> SCF type Self-clean filterNo need to change the mesh screen;Automatically discharge the impurities;Can realize 60mesh, 80mesh 100mesh and 120mesh./p>>> For different materials and different usage scenarios, we can provide you different pelletizing systems. Water-ring pelletizing system: Standard granulating method in ACS-H system; Self-adjusting pelletizing head ;RPM of rotatory blades is automatic./p>>> Under-water pelletizing system:Suitable for big capacity, automatically,Applicable to a wider range of materials./p>>> Water-strands pelletizing system:Cost-effective;Suitable for the material which MFI is higher than 8./p>>> Vibration: Sieve is made of Stainless steel ; Dewatering granules and selecting size.Centrifugal dryer:Horizontal-type which is lower energy consumption;Blower on the dryer to remove the moisture further;Equipped with sound-proofing cover to reduce noise.Product silo:All pipes and silos wrapped with sound -proofing cotton;Optional Capacity online monitoring & Quantitative weighing./p>>> Intelligence Start: One button only.>>> Intelligence Stop: One button only.>>> Emergency Stop: One button only.Remote monitoring and information transmission./p>

Informazioni basilari.

| Modello numero. | ACS-H |

| Vite | A vite singola |

| Invertitore | Invertitore |

| Riscaldatore elettromagnetico | Riscaldatore ceramico o riscaldatore a infrarossi lontani |

| Automazione | Automatico |

| Computerizzato | Computerizzato |

| Personalizzato | Personalizzato |

| Certificazione | CE, ISO9001:2008, TÜV |

| Condizione | Nuovo |

| Ubicazione della fabbrica | 2 ore di auto da Shanghai |

| Servizio post-vendita | Pezzi di ricambio gratuiti |

| Manuale campione/servizio | Disponibile |

| Controllo | Controllo PLC |

| tipo di affari | Produttore |

| Materiale | Ferro |

| Vantaggio | Motore di marca famosa |

| Prodotto finale | Pellet/Granuli |

| Compattazione delle dimensioni della stanza | 300-1400 litri |

| Applicazione | Pellicola, filamento, rafia, schiuma |

| Voltaggio | 380 V 50 Hz o personalizzato |

| Tipo di macchina | Macchina per il riciclaggio |

Potrebbe piacerti anche

Invia richiesta

Spedisci ora